Service First, Best Price, Customer First

1500+㎡

Standard Factory Building

10,000+t

Shipment Volume

25+Year

Experience

ISO9001

Professional Certification

QINGDAO TONGXIANG HUANBAO KEJI CO.,LTD.

Recognized as a Qingdao SRDI Enterprise and certified under ISO 9001, the company focuses on manufacturing ship components, automotive parts, mechanical components, and industrial automation equipment, providing both customized solutions and large-scale production with reliable quality.

Our products include ship components, automotive parts, mechanical components, and industrial automation equipment, offering both customized solutions and large-scale production with high precision, reliability, and quality.

Our company has strong business capabilities and proven experience, independently producing ship components, automotive parts, mechanical components, and industrial automation equipment. We serve leading enterprises such as SINOTRUK, CRRC Qingdao Sifang, and Qingdao Shipyards, with an annual production capacity exceeding 10,000 tons.

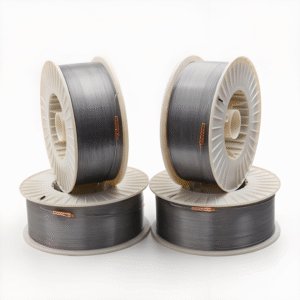

Shipbuilding Industry

The company possesses the capability to independently manufacture high-quality ship components, leveraging advanced production equipment, skilled technical staff, and rigorous quality control. This enables us to deliver precise, reliable, and customized solutions that meet the specific requirements of the maritime industry.

General Parts Manufacturing

The company possesses the capability to independently manufacture high-quality ship components, leveraging advanced production equipment, skilled technical staff, and rigorous quality control. This enables us to deliver precise, reliable, and customized solutions that meet the specific requirements of the maritime industry.

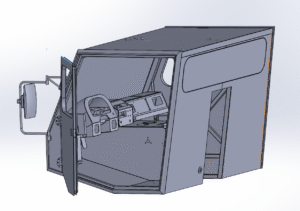

Automotive Parts Manufacturing

The company specializes in the manufacturing of automotive parts and accessories, combining advanced machinery, skilled technicians, and strict quality control to produce high-precision, durable, and reliable components. We offer both customized solutions and large-scale production, meeting diverse client needs across the automotive industry.

Industrial Automation Equipment Manufacturing

The company specializes in the manufacture of industrial automation equipment and related products, utilizing advanced production technology and skilled engineering teams to deliver high-performance, reliable, and efficient solutions. Our offerings support both customized designs and large-scale production, helping clients optimize automation processes and improve operational efficiency.

Why Choose US

Advanced Automation Machines

Equipped with state-of-the-art machinery, we deliver high-precision, efficient, and reliable production for both custom and large-scale manufacturing.

Mature Technology

With mature and proven technology, we ensure stable, efficient, and high-quality production across all products and applications.

Advanced Automation Machines

Equipped with state-of-the-art machinery, we deliver high-precision, efficient, and reliable production for both custom and large-scale manufacturing.

24-Hour Customer Service

We provide 24-hour customer service, ensuring timely support, rapid response, and continuous assistance to meet the needs of our clients worldwide.

Competitive Price

Stay updated with the latest company news, product launches, and industry developments.

Automotive Injection Molding: A Comprehensive Guide to Materials, Processes & Solutions

The automotive industry is undergoing a monumental transformation driven

The Evolution of Polymer Applications in Modern Automotive Interiors

The Evolution of Polymer Applications in Modern Automotive Interiors 1.1.

Engineering Excellence in Auto Interior Plastics

The Evolution of Polymer Applications in Modern Automotive Interiors 1.1.

OUR CAPABILITIES

Metal Stamping

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metalinto a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking.embossing. bending. flanging. and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part.orcould occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Progressive diesare commonly fed from a coil of steel, coil reel for unwinding of coil to a straightener to level the coil and then into a feeder which advances the material into the pressand die at a predetermined feed length.Dependina on part complexity. the number of stations in the die can be determined.

Stampina is usually done on cold metal sheet. See Foraing for hot metal formina operation

CNC Machining

Advantages of CNC Machining

Machining complexity often brings with it high-level requirements. To ensure that your parts meet your needs, we include design feedback from applications engineers.You’ll also get:

Tolerances as tight as +/-o.001 in.(0.0254mm)Fulfillment of quality requirements (including CoC,FAI, ISO go01, and ASg100)Fully machined features (no material left behind)

We do low-volume & high-volume orders, material-specific machining, sub-assemblies & more. We are a one-stop-shop for all your advanced design & machining needs.

CNC milling

CNC milling is a subtractive manufacturing process that uses 3-axis milling and 5-axis indexed milling processes to cut solid plastic and metal blocks into final parts.

Our CNC milling process produces custom prototypes and end-use production parts in as fast as 1 day. We use 3-axis milling and 5-axis indexed milling processes tomanufacture parts from more than 30 engineering-grade plastics and metals. With machined production parts, you can also get more competitive pricing at higherquantities in addition to first article inspection(FAl)reporting,material certifications,and additional finishing options like anodizing and chromate plating.

How Does CNC Milling Work?

CNC milling is a subtractive manufacturing process. It starts by fixturing a block of metal or plastic material inside the CNC mill. Using G-code, the CNC machine isprogrammed to rapidly mill out parts from the block of raw material Our 3- and 5-axis CNC machines are equipped with various toolsets to maximize efficiency andproduction speed.

Machined plastic parts are left as-milled, which typically means they show visible tool marks. Some metal parts allow more finishing choices like anodizing and chromateplating. When the run is complete and your required surface finish is applied, parts are boxed and shipped shortly thereafter.

CNC TURNING

CNC turning with live tooling combines both lathe and mill capabilities to machine parts with cylindrical features from metal rod stock.Our CNC turning process produces custom prototypes and end-use production parts in as fast as 1 day. We use a CNC lathe with live tooling so features like axial andradial holes, flats, grooves, and slots can be machined.

What is CNC Tuming?CNC turning is a subtractive manufacturing process that rotates a metal rod while a cutting tool is held against the stock to remove material and create final parts. OurCNC lathes are also equipped with live tooling that can machine flat features and holes into the workpiece. Outside diameter (OD) and inside diameter (ID) threading isalso available.

Turned parts can then be left as-machined, with visible tool marks, or bead blasted. When the run is complete, parts are inspected, boxed and shipped shortly thereafter.

We are qualified and for services

The Company follows a customer-oriented, service-driven approach, pursuing development through quality, credibility, and service.